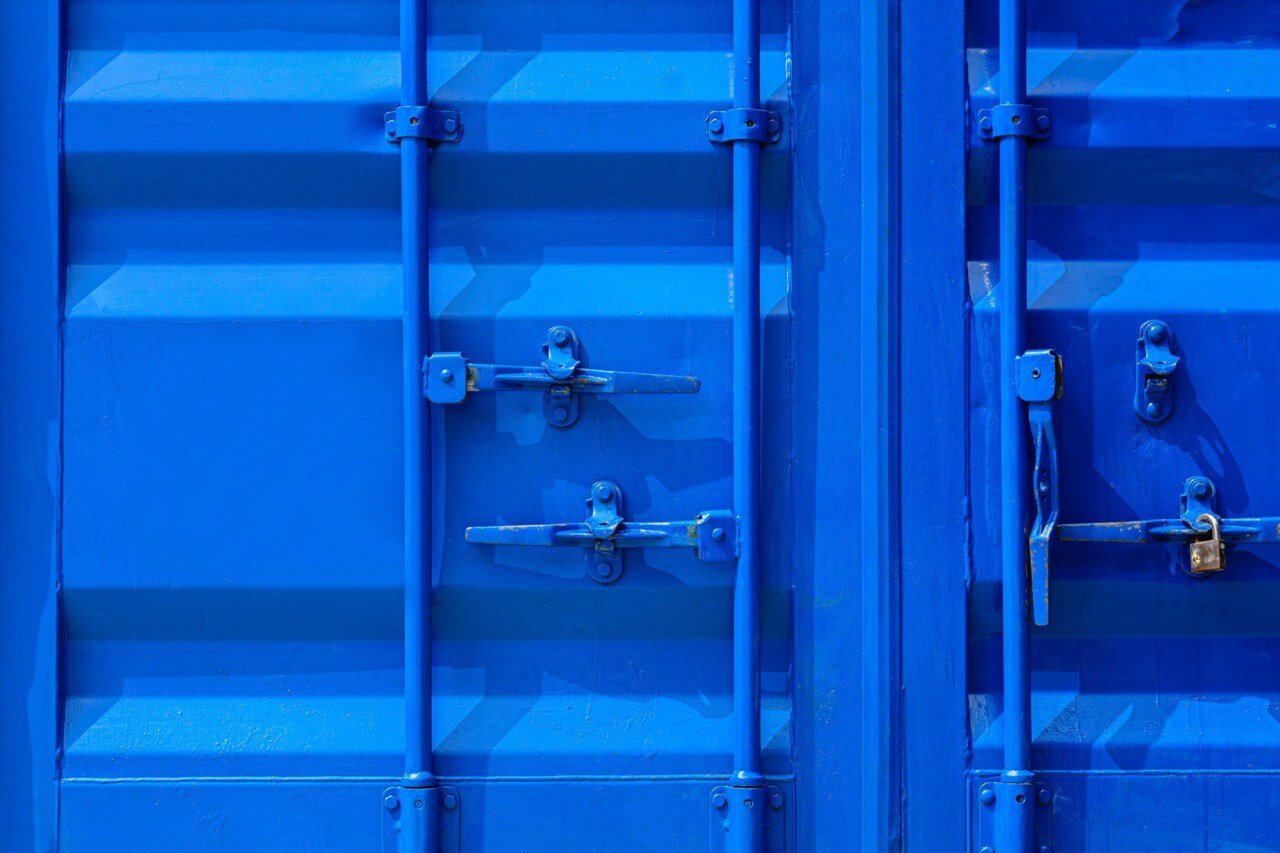

How to Buy a Shipping Container When You Can’t See It in Person

When you’re purchasing a shipping container, it’s completely normal to want to see what you’re buying. But since most containers are stored in active depots and container yards, and not retail lots, it’s often not possible for customers to see them in person. At Super Cubes, we understand that this ...